Search by Group *Products that do not match your search are under construction.

Search by Industry

Close

CLOSE

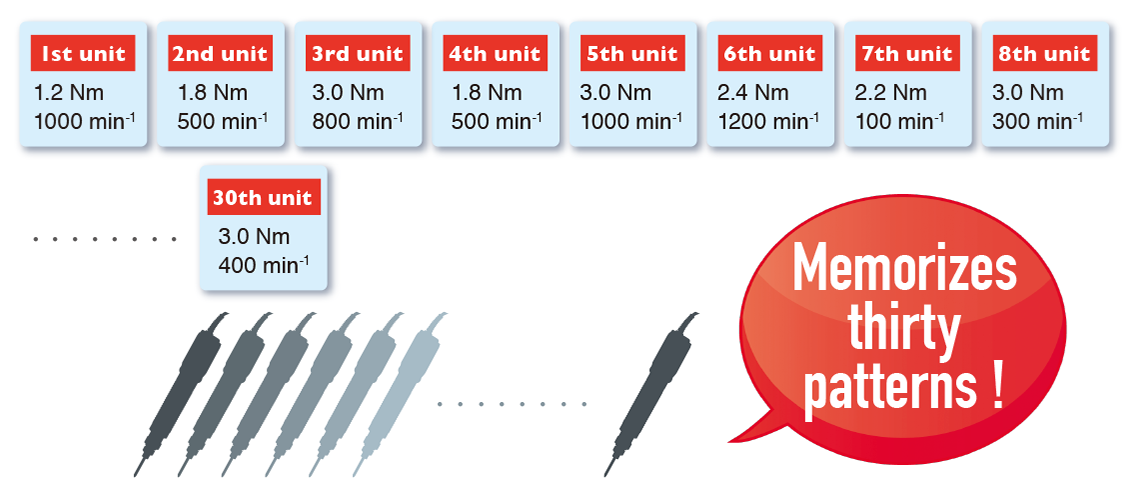

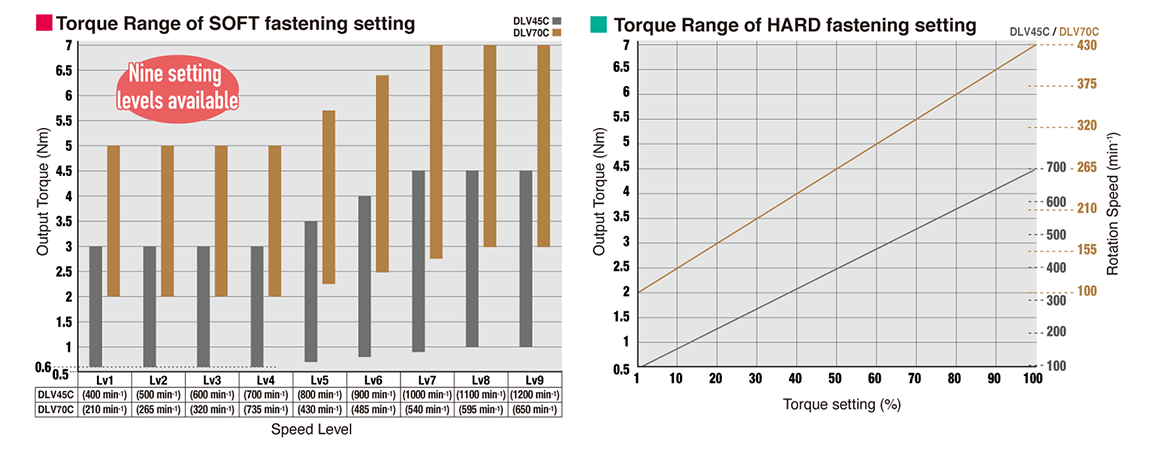

・There are nine levels for rotation speed setting. (DLV45C: 400 to 1200 min-1 / DLV70C: 210 to 650 min-1)

.

.

The screwdriver automatically reverses after torque-up or reaching the preset time.

When the fastened screws are unfastened, the number of counts can be returned.

Judges as NG(Fail) when operated longer than the set time.

Judges as "correct fastening" only when the measured time is between the upper limit and lower limit.

To measure torque with the Torque checker (optional)

All settings can be reset.

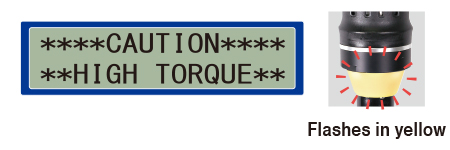

A torque value that alerts the operator can be set. After the channel is switched, if the torque exceeds the preset value, a warning is displayed on the counter and the electric screwdriver will not start.

To prevent additional fastening (second tightening, confirmation tightening, etc.), it can be set so that it does not restart after torque-up (for 0.0 to 9.9 seconds). Adjust the set value according to the skill level of the operator and the interval between screw fastening operations.

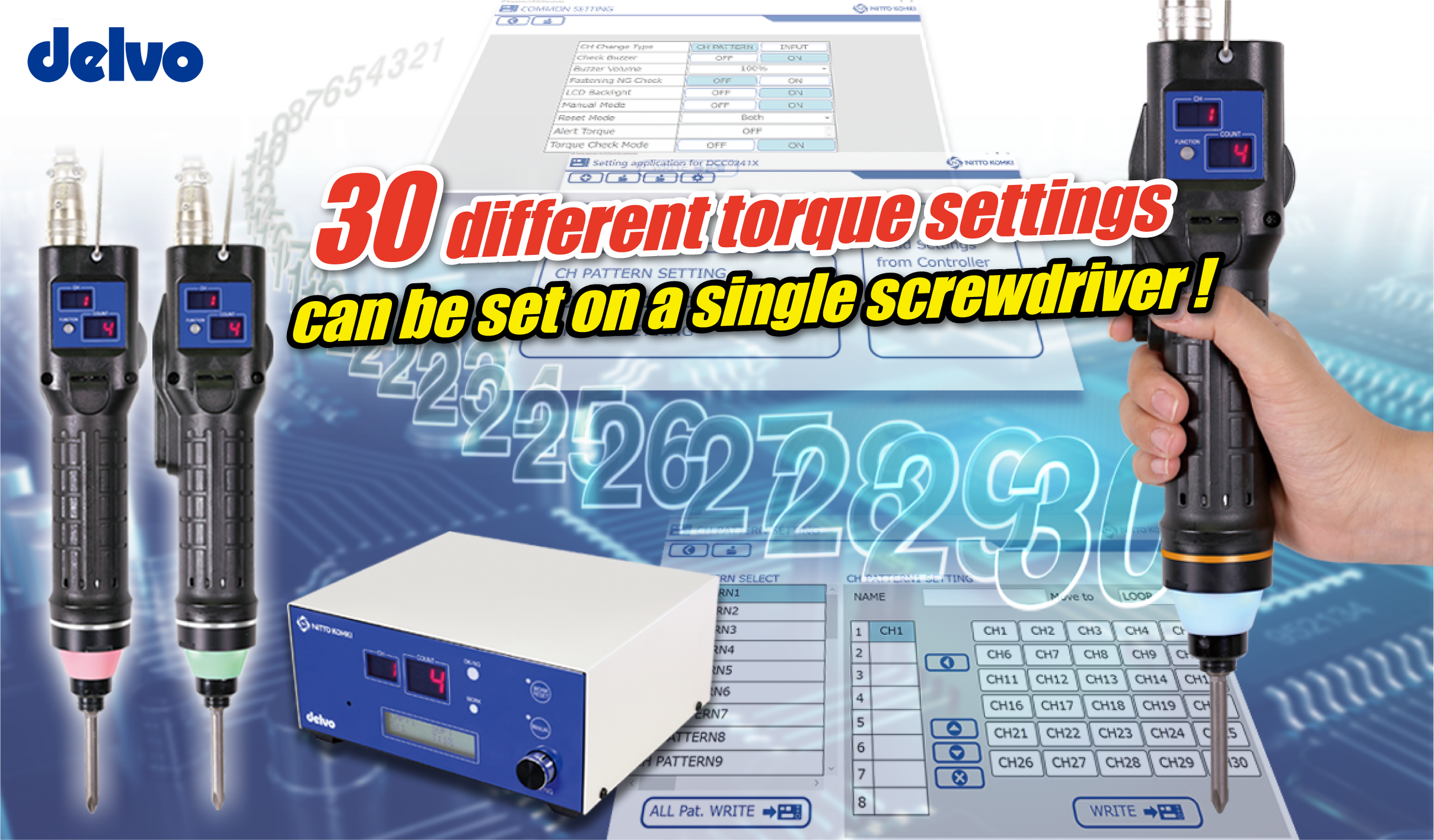

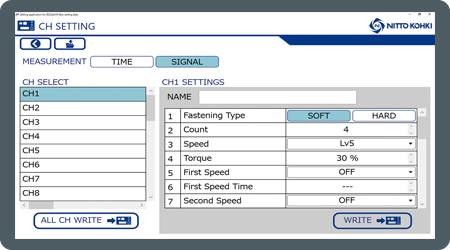

Channel setting

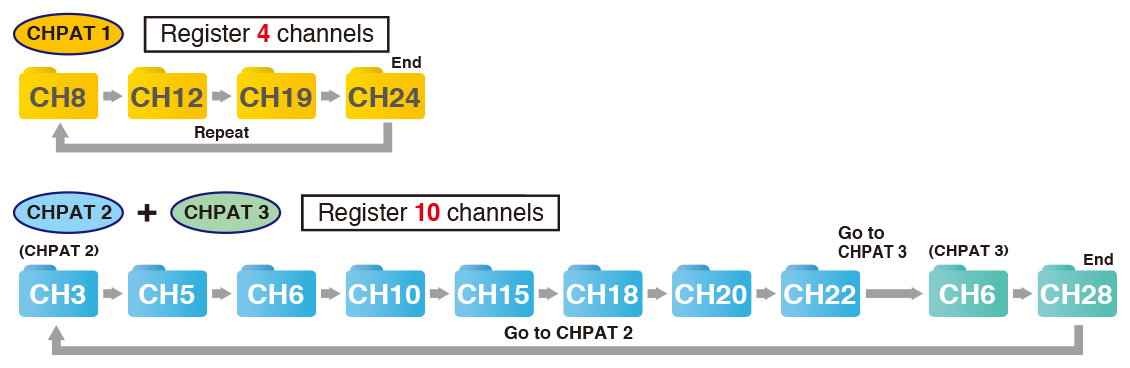

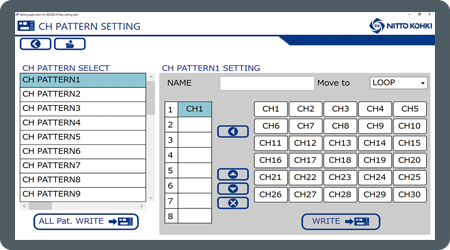

Channel pattern setting

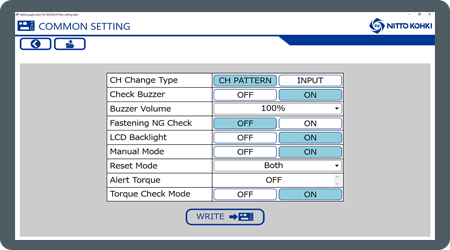

Common setting

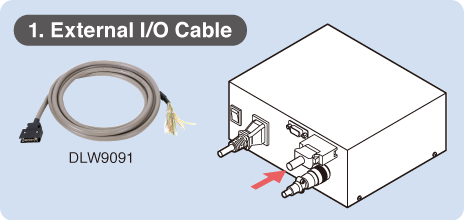

Insert the separately sold External I/O Cable DLW9091 to the external signal connector to connect between the terminal and wiring.

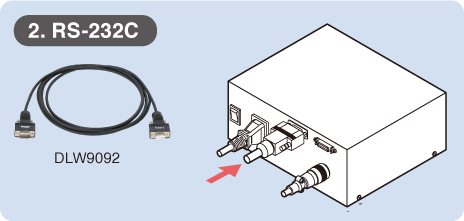

Insert the separately sold Communication Cable (Straight-through) DLW9092 to the RS-232C connector to connect to a PC or sequencer (PLC).

NITTO KOHKI Official YouTube Channel

© Copyright NITTO KOHKI CO.,LTD.All rights reserved.